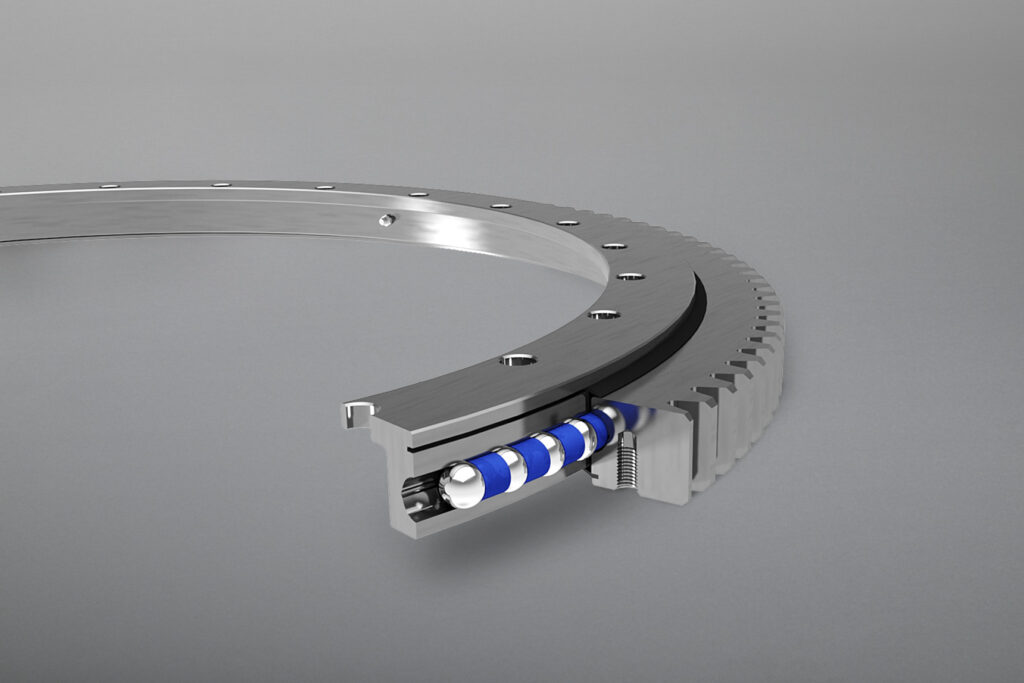

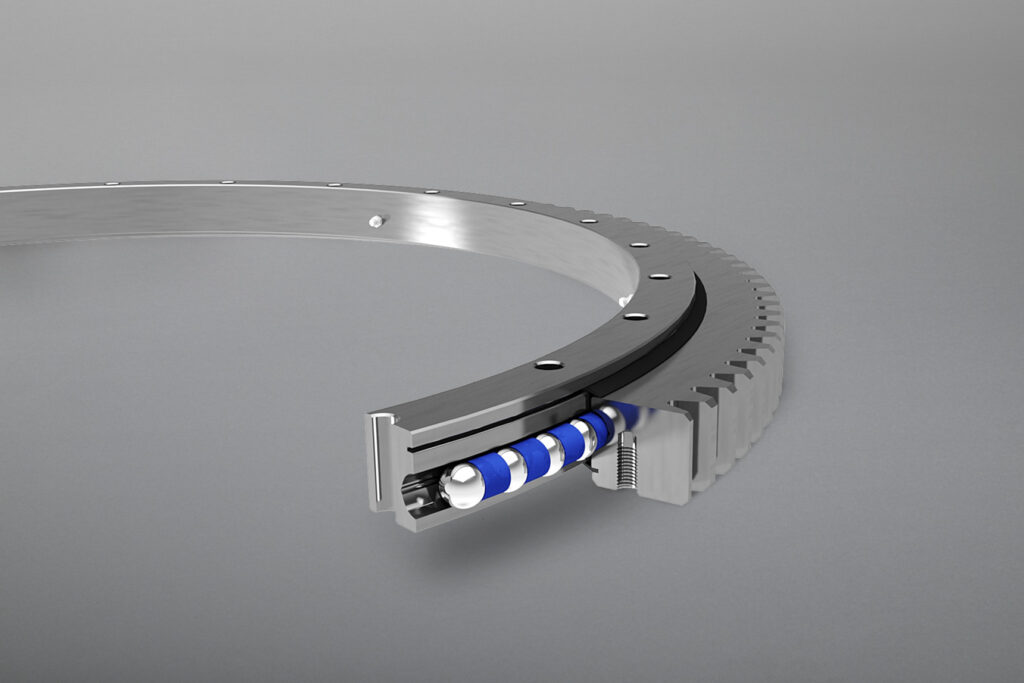

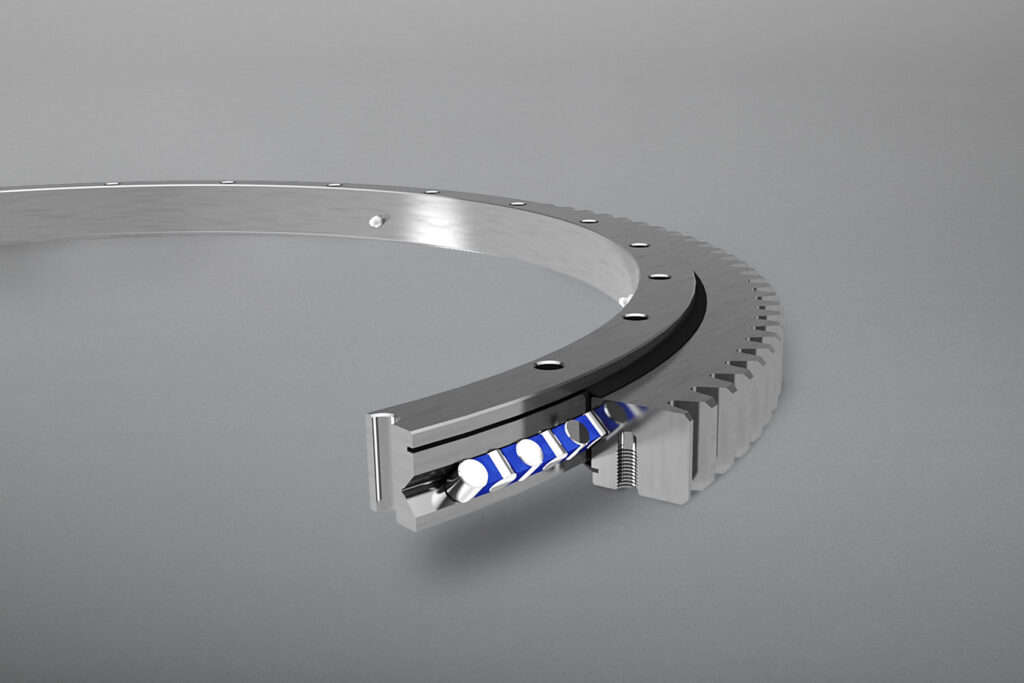

Slewing Bearings

Our product range comprises single-row ball slewing bearings in standard as well as flange design as well as crossed-roller slewing bearings, respectively with inner and outer gear but also without any gear. Different special models are in stock as well.

- Production Program

- Custom Made Parts

Materials for standard parts are quenched and tempered steels – 42CrMo4 and others; for customized solutions we also process various stainless steels – such as X45Cr13 – for example

- External and internal gear module: 3 – 24

- Straight and helical teeth

- Turning, drilling, gear-cutting and hardening generally up to 5000 mm

- Gear quality: 8 – 12 (milled)

- Gear tolerance block: 27

- Sealing: standard parts are fitted with simple lip-seal profiles at both upper and under side of the slewing bearing; for custom made slewing bearings and use in very harsh environments, multi-lipped seal profiles are also available

- Testing of hardening depth with ultrasonic measurement

- Quality assurance through simulation and test run after complete assembly at the factory

- 100% testing

Other modules and larger diameters on request.

Individual, non-standard designs can be produced for special conditions and applications (e.g. extreme temperatures, exposure to dust and dirt, slewing bearings with suspended fittings, as well as high loads, torque, or rotational speeds). All requirements can be discussed in detail with our design engineers.

Overview of our special solutions:

- Precision bearings with centerings

- Preloaded bearings

- Types with increased number of screws

- Steel or brass cages and spacers

- Special surface treatment such as paint coating, zinc coating or chromating)

- Special sealings (chemical resistant types, steel labyrinth sealings, high and low temperature versions)

- Special greases

Slewing Bearings Overview

This section contains a selection of our products with further links to the respective technical specifications. Didn’t find what you were looking for? Contact us and we will be pleased to advise you on your project.

Overview of Types

- Four-point contact bearing, light design

- Cost optimized type

- For standard applications

- Transmission of moderate loads and torques

- Suitable for connecting structures with low requirements on accuracy and stiffness

Applications:

General mechanical engineering, light turntables, materials handling, railed vehicles

- Four-point contact bearing

- For tough service conditions

- Cost optimized type

- Insensible to vibrations

Applications:

Cranes, building machinery, plant and mechanical engineering, wind turbines

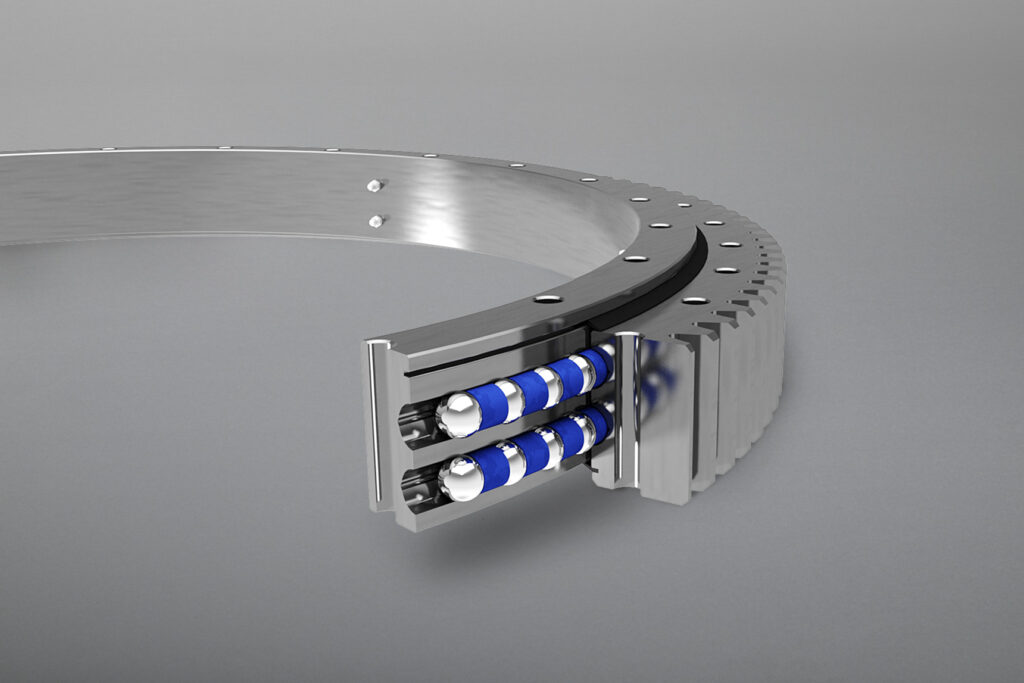

- Eight-point contact bearing

- For high static and dynamic loads

- Insensible to vibrations

- Suitable for rough connecting structures

- Also available as double axial ball bearing

Applications:

Wind turbines, transshipment technology, general mechanical engineering

- High accuracy

- High stiffness

- Uniform rotational resistance despite changing loads

Applications:

Machine tool engineering, tunnelling machinery, positioning systems

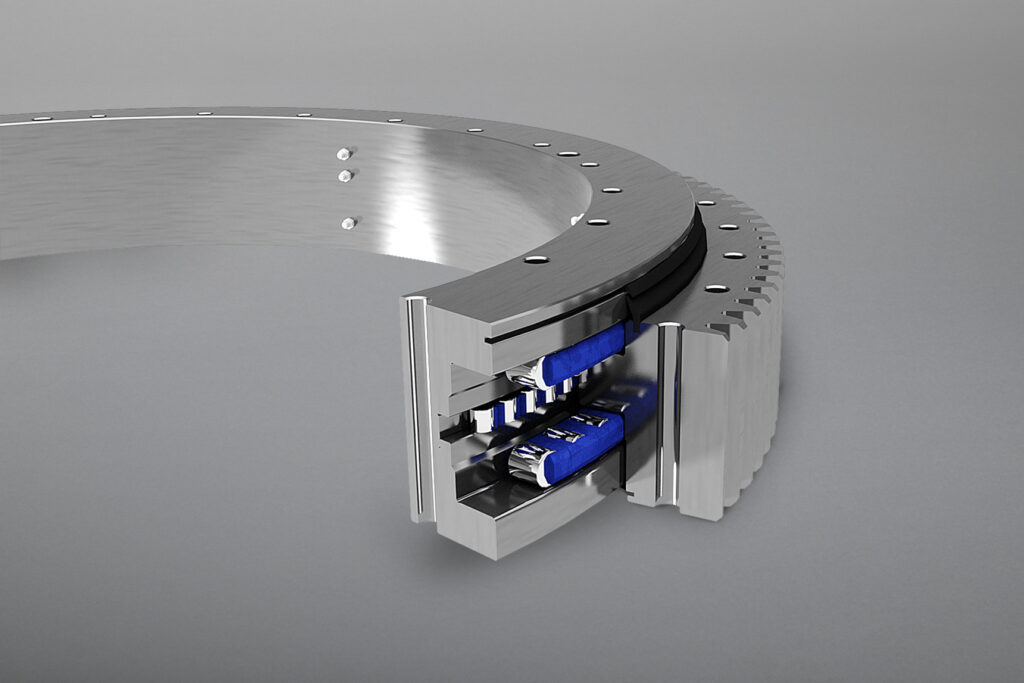

- High accuracy and stiffness

- Very high static and dynamic load capability

- Suitable for highest axial loads and tilting moments

Applications:

Offshore technology, transshipment technology, wharf cranes, belt stackers, large antenna systems